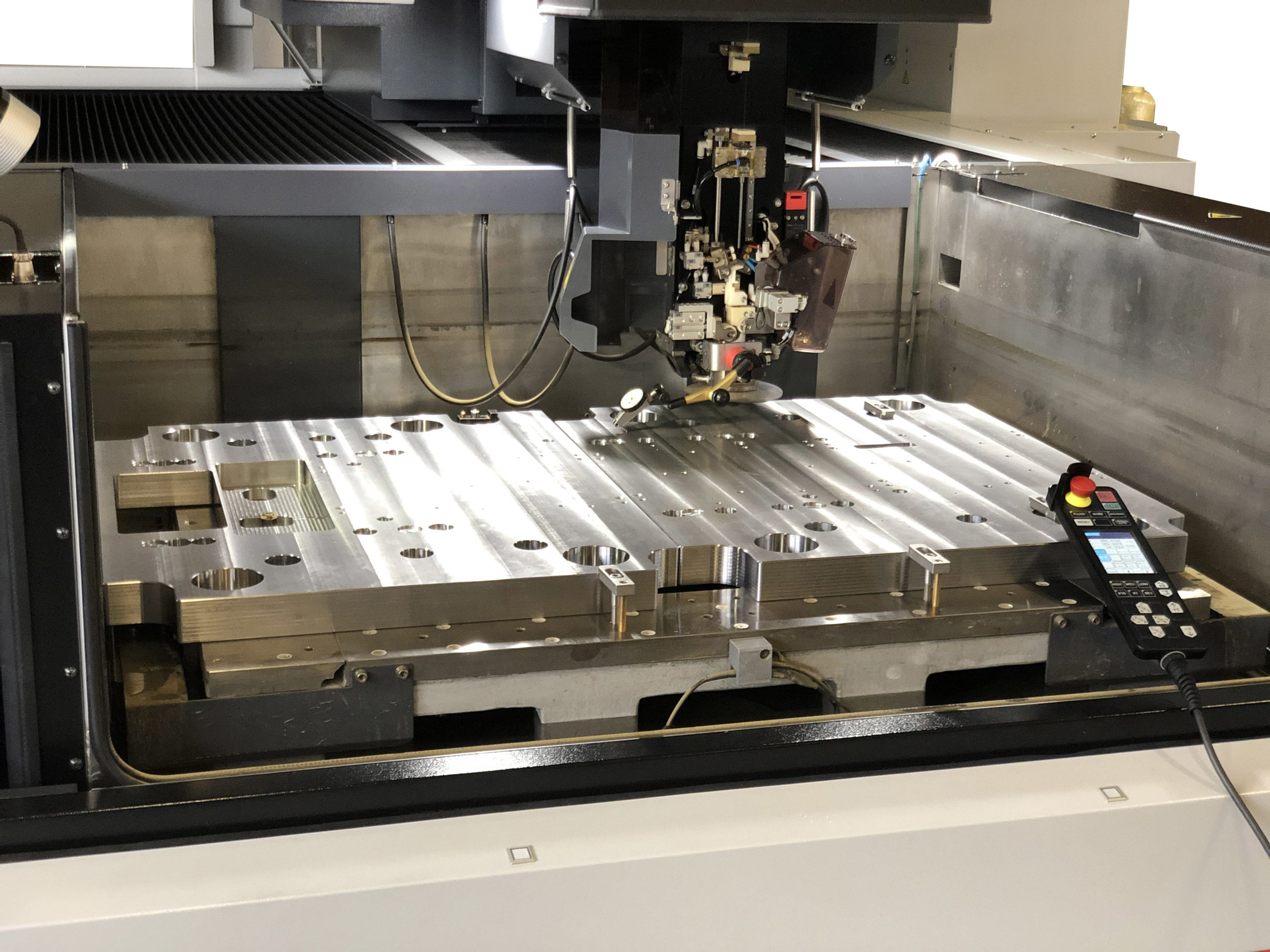

Our machine fleet is continuously renewed and subjected to maintenance to ensure the utmost precision in the shortest time possible.

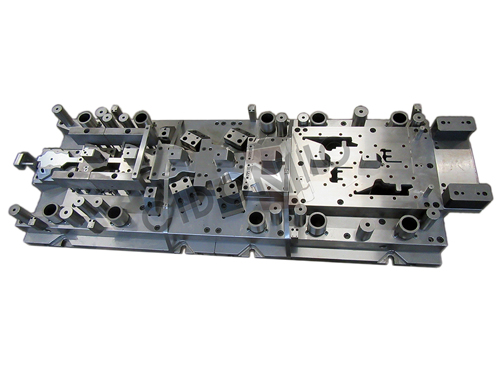

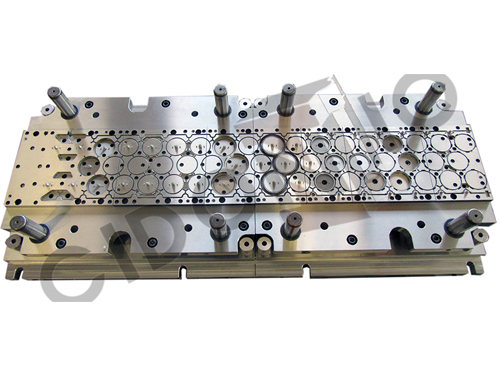

We have been using 3D design for many years now, which allows for the virtual simulation of all the die’s movements before it is built. This enables us to make even complex dies.

All of our products are designed using state of the art CAD software. The vertical machining centres are programmed with 3D CAM technology from a work station. Our internal data network allows us to transfer data in less time, thereby avoiding hardcopy drawings. We are equipped with CNC machining centres, n.4 WEDM (immersed or continuous water jet), and EDM machines.

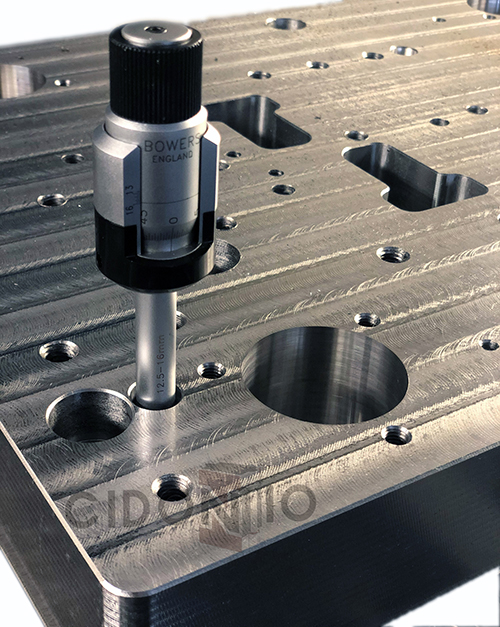

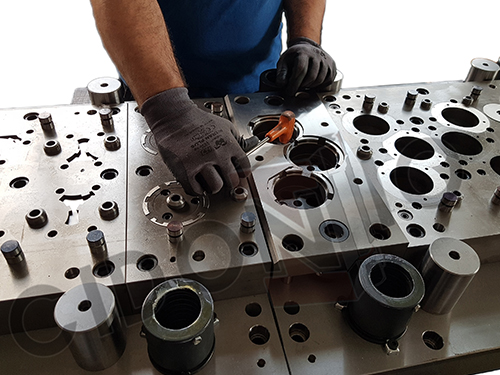

We also have various electronically controlled tangential grinders with working range between 2000×1000 cm and 500×200 for final precision works during the assembly stage. Dies are inspected by specialised companies by measuring sample pieces using dimensional inspection machines.

Every order is managed and monitored with consideration for time and costs, relying on monitoring and control software.